From a pile of timbers, he seemingly conjured a work of art. Gold, of a sort.

The breezeway, added in the 1830s to the House that Moses Chaplin Built, gave rise to a pile of timbers after its gentle deconstruction.

The timbers sat stacked in the yard for two years, awaiting their new fate.

Ed suggested the timbers be a feature in the reimagined breezeway, now to be an open kitchen and living room space. They could be a prominent feature of this “great room”. The details–the many design possibilities, stacked up against the offsetting realities of available material–could wait until installation time. And for the right person to do the work.

As it happens, the right person was a family member. Our nephew Jay is an outstanding carpenter, with a love of, and talent for, timber framing. We were elated when he agreed to take on this project!

It was a joy to watch Jay practice his craft, and to see the efforts of the supporting cast that made this all come to fruition. The basic steps, as seen through my lens as a highly interested, and very novice observer:

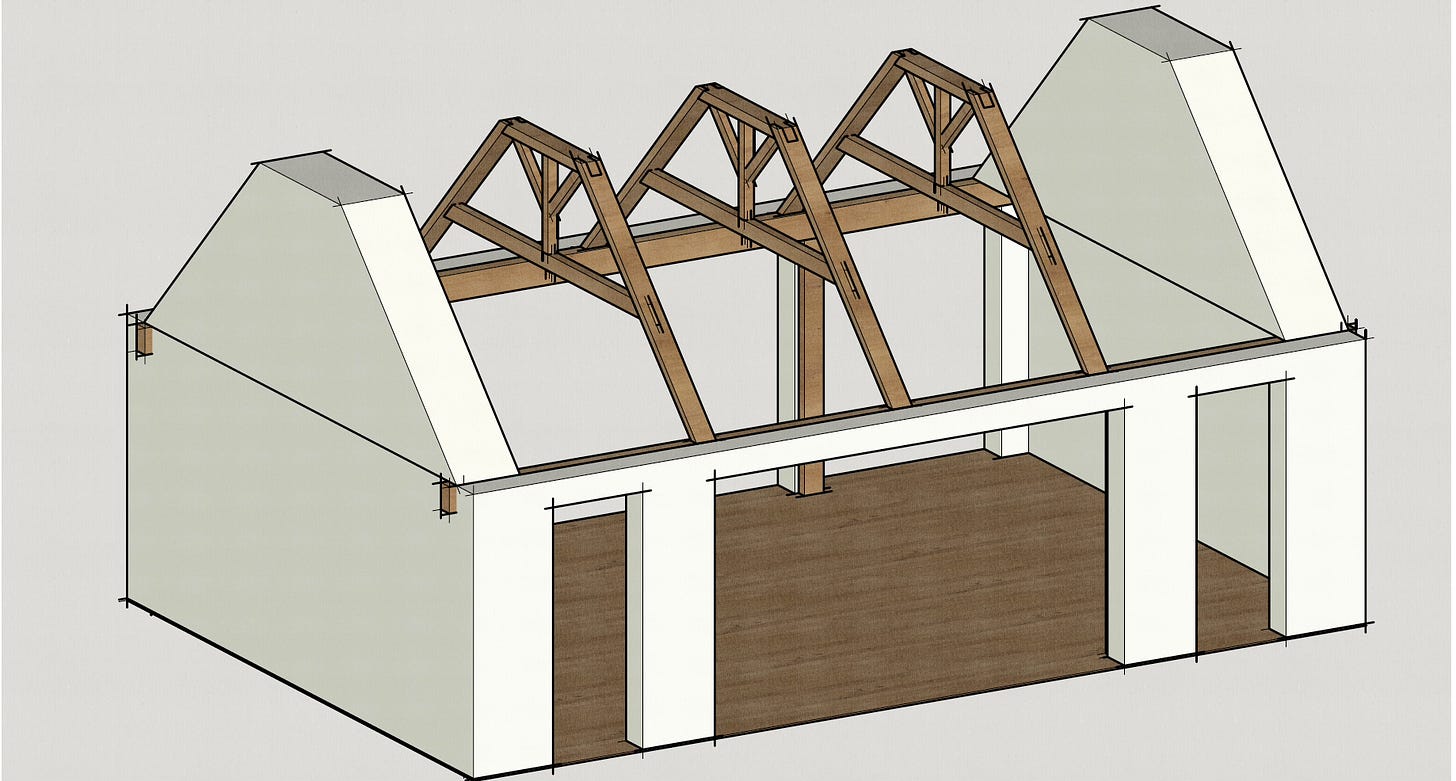

Design. The timber frame structure (trusses, beams and posts) was intended to “read” as structural, even though it would be applied to the surface of the standing structure as a decorative element. Room scale, timber availability, and Jay’s creativity and stylistic preference, led to a king post truss design1. The trusses were relatively evenly spaced in the room, and positioned to look like they were tied into beams that ran the length of the room and sat atop posts that span from the floor to the beams. The truss spacing, and the beam positioning to die into (and seemingly pass through) the end walls, both suggest there is one more truss hidden in each of the end walls (but now you know the truth).

Prep the space. The Snowdog team used Jay’s design to prepare for the trusses: Framing a flat ceiling and soffits on the end walls that complete the illusion and provide a convenient place to hide wires and ductwork; adding “blocking” to provide anchor points for the fastening of the timbers to the structure; installing a finished ceiling of nickel gap boards, against which the timbers can be set flush. The work to prep was happening simultaneously with the first steps of timber framing…it was a race to be ready in time!

Prep the wood. Jay sorted the timbers in short order, marking select pieces for future processing. Jay and Nell (who worked alongside Jay throughout the entire truss project) then pressure washed all the beams. Shout out to my neighbor Bill for the pressure washer loan!

I was surprised to learn that the gray patina I had long admired in those beams was, for the most part, just accumulated dirt and mouse “leavings”. Turns out, sunlight is what most often creates the grey patina on wood. Most of these timbers would have been felled and used green, with little chance for sun exposure before they were tucked in the home. So, while a few clearly saw the light of day for a while and remained gray after washing, most were just filthy. They took on a nice tan hue when washed, and smelled a lot better too!

Cut the wood. Cleaned timbers were cut to rough lengths, and then Jay ripped the biggest ones down the middle lengthwise. They were halved so the cut side could lie flat on the surface to which they would be attached, helping create the illusion that they are full thickness and extend through the plane of the wall or ceiling. After ripping these beams, Jay scalloped out a little of the middle of each cut side with some deft chain saw work so that the edges were the highest point and would be sure to make contact before any other part of the beam. Clever fellow!

Rip it, scallop it, and move on! Time lapse of Jay in action.

Lay out, cut, and assemble trusses. The truss layout process involved first resting each framing element to be joined in successive, perfectly level layers, and then using a plumb bob and chalk line to mark precise angles for cutting, which helped ensure the pieces fit together tightly (oversimplification warning!). Once marked, out came the hammers, chisels and drills. Wood chips were flying, but it was the quiet focus of a true craftsperson took over in these critical moments! After a period of exacting measurements and precision cutting…..the first truss was assembled as a test fit on the floor.

Jay and Nell get after those truss pieces! Time lapse above.

Put up the trusses! After the trusses were test fit, it was time for the raising! With some heave-ho from all of us, and the physics of a lift, the first truss went up to its spot, and was tight set in place. When Jay was happy with the fit, long screws were used to fasten through the large timbers, through the ceiling, and into the blocking the team had set for just that purpose. This was repeated for the other trusses.

It takes a village to get the trusses in place!

Beams and posts! The setting of the beams that span under the trusses, and the posts that run from the beams to the floor, was less complicated. Jay made a “Jupiter” join (below) to attach sections of beam to create a piece to run the length of the great room, one for each side of the room, after which posts were cut and set to be tight between the subfloor and the beam.

Screws served as the attachments here as well. All went well until the very last screw of the very last section. Jay was giving it just one more twist when suddenly the lights flickered and went out in the great room. The screw had gone a little askew and straight through the wire that fed the ceiling lights. It was almost a relief that the invariable “thing that goes wrong” for the truss project was so easily remedied (by a good electrician), and didn’t involve very heavy trusses at height, or big saw blades hitting embedded nails, or other, more onerous possibilities.

Celebrate! Once the work was done, we had our first of what I hope will be many dinners in the great room with friends and family.

Throughout the dinner, I couldn’t help but stare upwards. I still can’t, almost each time I walk in the room.

I wonder at the journey of these timbers.

From trees that started growing in the 17th and 18th centuries, into the hands of craftspeople hundreds of years ago. To a tour of duty as the internal skeleton of the breezeway from the 19th to 21st century.

Then, a brief respite in our yard. Or was it a rest at all, out in the snowy cold, and driving rain, and blazing sun, with mice nesting in this or that mortise? But then, a shower to clean off the grime from almost two hundred years of holding up the breezeway.

Finally, into the hands of the alchemist and his team, who transform these pieces of timber into a new shape. A new purpose.

No longer to bear the weight of “structure”.

But rather to watch over and delight those who gather, who dine, who live, who love, who pass on and make way for new ones who will do the same, in their own way.

The alchemist made gold, indeed.

Jay once told me that his reason for choosing the king post truss would be obvious when we were able to see them up with the lights on.

His reason?

The beautiful shadows they cast.

We most certainly agree.

————————————————————————————————————————————

A little morsel. We were honored to have been chosen to be part of the 2024 Northeast Sustainable Energy Association (NESEA) Protour series. In August, we hosted about 50 folks– tradespeople, engineers, architects, sustainable energy aficionados, etc., who came to learn about the approaches we have taken, and lessons learned to date, as we work towards our Net Zero Energy Retrofit and Expansion of a 1782 Vermont Farmhouse. It was inspirational to be in community with others who seek to enable a healthy and sustainable built environment, and we were delighted to have an opportunity to learn from their excellent questions and ideas.

And, finally…I just went to the most recent NESEA Protour featuring the amazing work of New Frameworks in Burlington. New Frameworks is manufacturing low embodied carbon straw bale panels, and using them to build, amongst other things, Accessory Dwelling Units (ADUs) that are going straight after the affordable housing crisis in VT. The ADU we visited was BEAUTIFUL, outside and in! Can you believe that has straw bales in the walls?

Well crafted story as well, Brian. Thanks for the detail.

So very exciting, and beautiful. The whole place is coming alive!!