I was at the spring 2023 Northeast Sustainable Energy Association (NESEA) Building Energy Boston Conference when I realized something was amiss.

It wasn’t the conference. I’d attended the annual NESEA conference for a few years, and the agenda was once again dynamic, educational, and inspirational. It had a great lineup of topics on sustainable building, building science, embodied carbon, renewable energy deployment, workforce development and diversity, and so much more.

The issue was I had missed lunch, and I was hungry.

When I’m hungry, small concerns can occupy a disproportionate amount of headspace. The feeling is a bit like how I imagine “hangry” to be (my family says I am prone to this, but they’re wrong). The feeling I’m describing is better termed “hanxious”. At that moment, the “hanxiety” I was feeling was about our project timeline.

It was clear by this point that the Snowdog team–mighty to be sure, and also pretty small–had taken on a big challenge with our project.

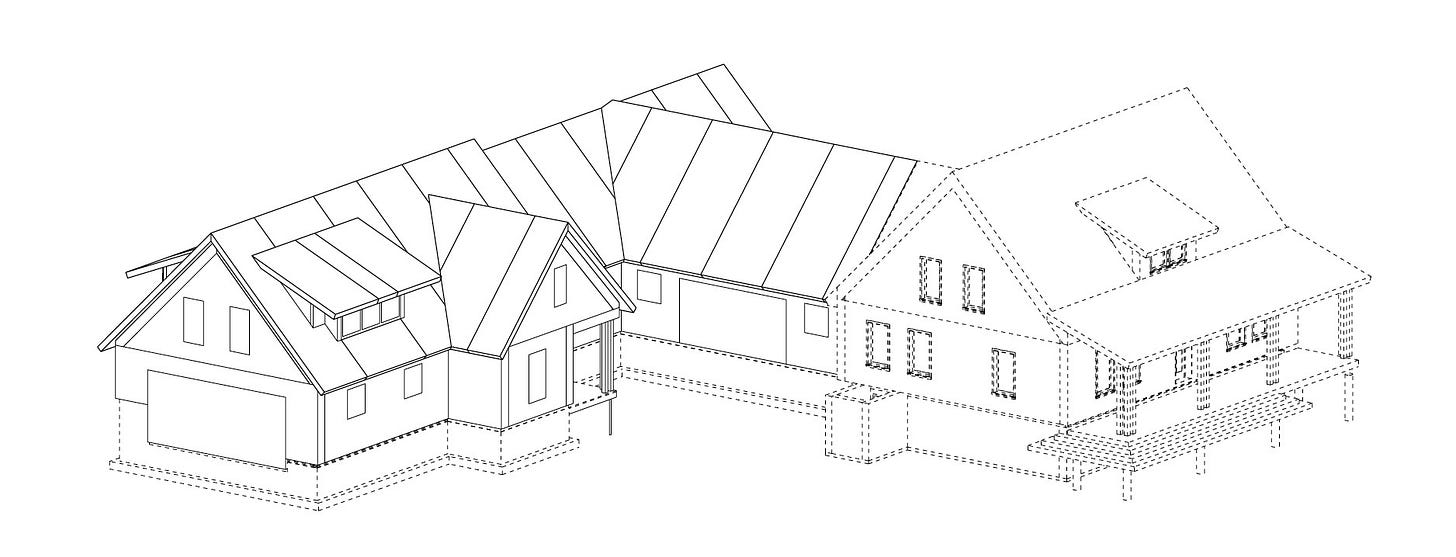

In reality, it is two projects: (1) an energy retrofit of an 18th Century home, and (2) a single story two-bedroom house with attached garage and loft to be added on to the aforementioned 18th Century home. Project 1 consumed nearly all of our time and effort to that point: working to repair rot, prep the foundation of the existing house for the planned “fatting out” of the walls and roof, tilting in a gable end, constructing a straight, level and plumb exoskeleton over the original house, and so much more.

My “hanxious” mind was saying “At the rate we are moving we won’t be done until 2030! We haven’t even started to nail a single piece of wood in place for the addition! The foundation for the addition, poured almost six months ago, looks the same as it did on day 1….and it is laughing at me!”

To compound the issue, we were at the front end of the relatively short Vermont building season, and efforts to find subcontractors to do the framing for the addition were not proving fruitful. That was a fact, not low blood sugar-induced exaggeration.

There was only one thing to do. I went to find a snack in the exhibitor hall.

After scoring a cookie (oatmeal raisin, if memory serves), and cup of tea, I was rushing off to the next talk when a presentation in the exhibitor hall caught my eye.

The presenters were showing photos of high performance windows (much like the Sublime windows I had seen at, and then purchased after, a prior NESEA conference), being installed into a fully insulated wall assembly. What surprised me was the window installation was happening in a climate-controlled warehouse.

I stopped and listened to them describe their process for offsite construction. I had heard of “prefab” before, but this sounded different than some of the associations I had with that term. The presenters were using phrases like “achieving passive house standards of airtightness and insulation”, “aiming for low embodied carbon”, “minimizing waste, and supporting sustainable forestry practices ”, “fully enabling net zero, electrified homes, even in northern climes”.

My key takeaway was that they could do much of the construction of a home–a net-zero ready home, for owners that cared about embodied carbon, waste reduction and safe building materials–at a very high level of precision and quality, in the controlled environment of their indoor facility. The house is constructed as a series of large panels of wall, roof and floor assemblies. The panels are then brought to the site, connected to each other and the prepared foundation in just the right order, and voilà: a fully weathered in, well airsealed, well insulated house, ready for the final exterior cladding and interior mechanical and finish work!

My blood sugar was rising, thanks to the cookie. And my enthusiasm for what the offsite construction approach could mean for our project was rising as well.

There were many questions to be answered, and diligence to be done. But…what if we could partner with this group? That would mean Snowdog could focus the building season largely on getting the original house all weathered in and insulated, while the other team implemented Ed’s architectural vision for the addition. And then, at the right time (i.e.--hopefully any time before there was three feet of snow on the ground!), the building envelope for the addition could be finished on site, bringing together the newly retrofitted original house and the new addition. That would be awesome! It could address so many of my concerns, some of which, I will admit, had been there for a while…even when I wasn’t “hanxious”.

So, I grabbed a business card, and later that day gave Ed and Michael a call to start the process of exploration. The initial list of questions:

Would they be able to work with Ed’s drawings, or do they require you to use a design they have created?

While the addition is essentially a stand-alone house abutting the original house, it needs to be perfectly tied into the original house and have the same architectural aesthetic. Floor levels, window heights, roof lines, trim details, etc. all need to line up perfectly so the resulting house is one home. Would they be willing, and could they, achieve that level of precision?

We’d already poured a 6-inch foundation wall, which is thinner than typical, and we didn’t have a concrete slab under any of the living areas in the addition. These were done to minimize concrete use, a major contributor to the embodied carbon of a new build (covered here). Would they be willing to adapt to thinner foundation walls and our unconventional floor system?

Could they achieve our targeted level of performance, while doing all of the above?

Would they truly support our goals of minimizing embodied carbon?

Did we feel aligned on values?

Would they fit the budget?

The short version: the answers to these questions were “yes”.

And since midsummer, we have been thoroughly delighted to be teamed up with the folks at the company in question: Bensonwood. I will have more to share about Bensonwood, their capabilities and process, and our experience, in other posts.

But for now, let me say that every time I look out at the foundation, instead of feeling anxiety, I feel great. Because I know that the Bensonwood team is hard at work translating Ed’s original design for the addition into a fully enabled offsite construction plan.

In less than two months from the date of this post, the Bensonwood installation crew is scheduled to arrive on site to do the finish assembly for the addition. Construction inside their facility begins in a few weeks. They expect that within two weeks of their arrival, we will all step back and admire a fully weathered in building envelope for the unified house.

Sometimes, the search for a cookie can lead to surprising outcomes!

A few other morsels

The exoskeleton has now been covered in sheathing and a new roof system, and is nearly ready for insulation and window/door installation!

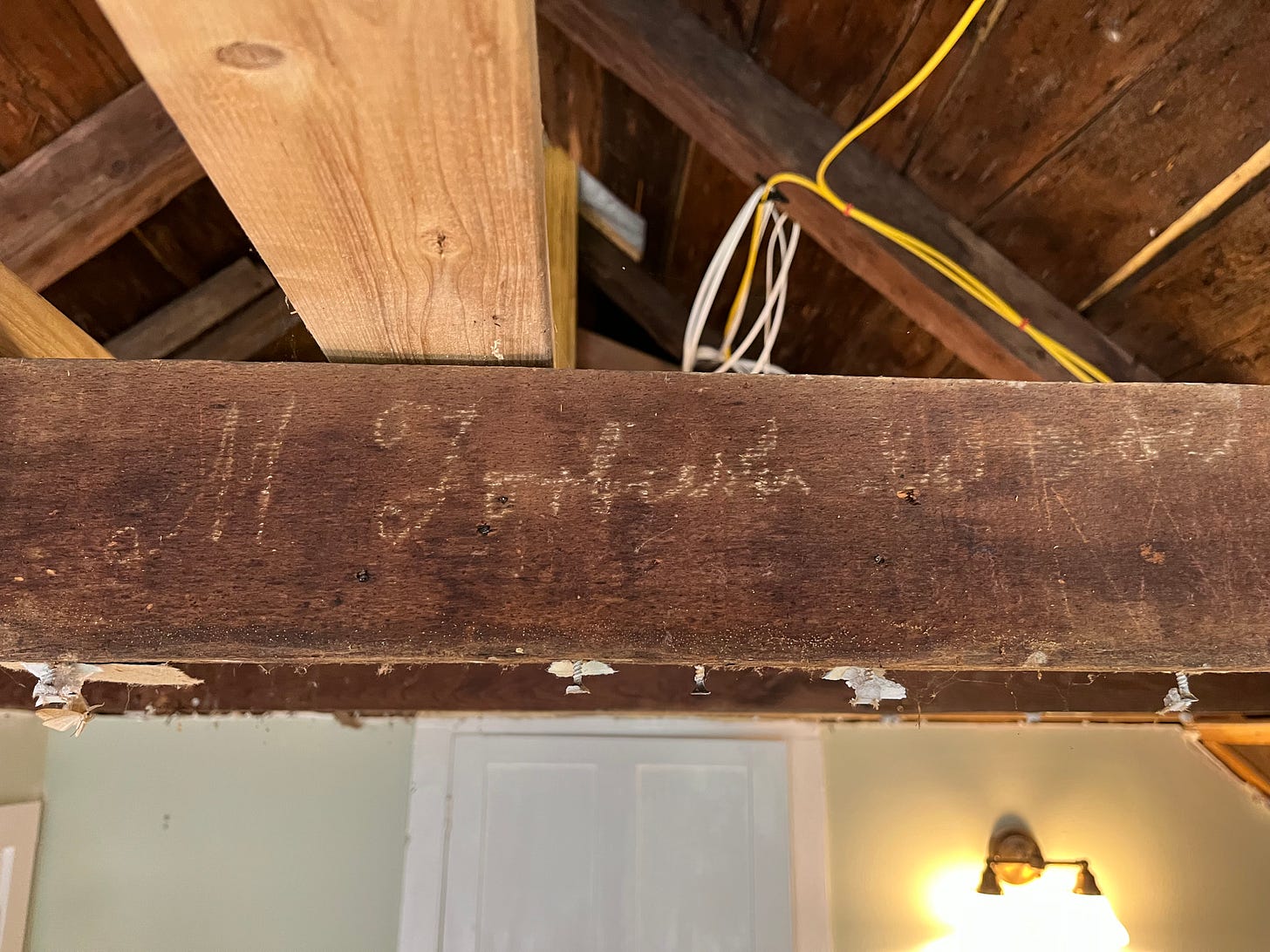

We’ve begun inside work on the existing house on rainy days (unlike Bensonwood, we can’t do work on the building exterior when it pours, which has happened a lot the last few months—sometimes disastrously so). The inside work involves moving the upstairs bathroom and renovating the bedrooms. In a prior post, I mentioned that the rafters of the existing house above one bedroom had the names of two prior owners painted on them, alongside the years they replaced the roof–”Copeland, 1929” and “Millard, 1991”. We were delighted to discover another piece of “roof structure graffiti” during demolition, this one on a rafter tie in that same room. We plan to vault the ceilings in this bedroom to expose the original rafters and ties, leaving some house history on display.

The beauty of this setting never ceases to inspire. The other day, the sun and rain–and physics–conspired to create a full spectrum rainbow over the house site at the end of a full work day. It restored me, physically and mentally.

My grandparents built a summer house that came in pieces on a truck in 1969. I'm guessing this method has been perfected nearly 50 years later. Kudos to the Cali/Evett family for keeping an open mind, holding your goals and looking for the best solutions you can find.

What an awesome blog, we went for a visit and saw they graffiti of the previous owners when they did their expansions and roof repairs. This is history and Brian and Sophie need to put their names on the same timber, maybe a plaque with the construction dates. Can’t wait to see all the parts come together.

Looking forward to the next update, make sure you have some cookies in the house for when you need energy.